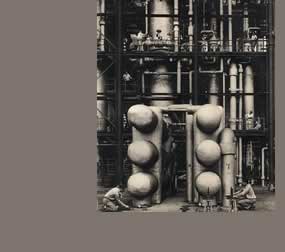

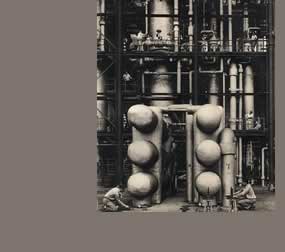

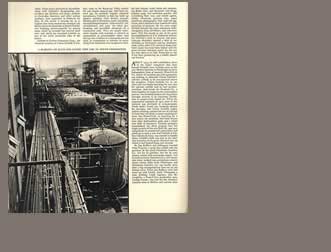

In an interview, Adams described

working under severe time pressures for FORTUNE, taking two weeks, day

and night, when he needed months. Taking the photograph of the electrical

furnace in volcanic conditions, he was dressed by the company in an asbestos

suit with an asbestos shield for his camera. Elsewhere Adams reveals

how inaccurate were many of FORTUNE's industrial features. He saw the

magazine as a vehicle for its advertisers. There are other fascinating

details of working for FORTUNE at

FULL

TEXT An

Interview with Ansel Adams Conducted by Ruth Teiser and Catherine Harroun

in 1972, 1974, and 1975, THE BANCROFT LIBRARY,

THE UNIVERSITY OF CALIFORNIA FULL

TEXT An

Interview with Ansel Adams Conducted by Ruth Teiser and Catherine Harroun

in 1972, 1974, and 1975, THE BANCROFT LIBRARY,

THE UNIVERSITY OF CALIFORNIA

"Several things I did for Fortune were preliminary

in anticipation of the war. I never realized it until later. But the people

who knew just said, "We're going to be in this, and we'd better get

ready." I

photographed [for Fortune] the big electric furnaces of Union Carbide in

the town of Alloy [West Virginia]. Unbelievable. I don't know how they

work them now, but the electrodes carbon arcs a single arc three feet in

diameter, nine feet long, and three of them are screwed together. They

were cast with threads, so they'd be screwed together into a single arc

twenty-seven feet high carbon. And they would be grouped together in threes,

operated by hydraulic controls, and the cauldron was as big as this whole

place forty feet across. The voltage was only six volts, but it would have

a tremendous amperage. And the current comes in in folds of copper not

wires, but just thick bands ribbons of copper. Well, anyway, these great

carbon electrodes come down into this mix slowly come down and make the

contact, and it's just like a volcano! It displays absolutely tremendous

power. They had a hydroelectric plant just for that purpose in that area.

Now, getting back to this photography for Fortune , the

photography of the electric furnaces at the town of Alloy, which is up

the Kanawha River. I described these great electrodes, which were three

feet across and twenty-seven feet long three of them bunched together.

And the tremendous amount of electric power required. And when these things

touched the mix (I think they call it the mix), it's something like a volcano.

And they keep burrowing in, and producing tremendous heat. And finally

the material starts to melt. It is steel and various alloy chemicals making

up certain crucial alloy metal. Nobody is supposed to be in that place

when the contact is made, because it'd be like being on Mount Etna during

an eruption, you see. Well, I said I had to be there to make the photograph.

So they made me an asbestos garment, and they made an asbestos shield for

the camera. And I would stand there under the shield with my hand on the

cable release, you see. One could see just the lens and my goggles. When

the process began, I thought, "What am I doing here?" Pieces

of molten metal were coming at you. And after about five minutes of this

it quiets down and just starts to melt, and then finally the carbon arcs

are used up. You see them dropping, slowly dropping into this incredible

blue-white heat. I forget the temperatures. I think it was over 4000. It's

one of the highest temperatures used in metallurgy. I wouldn't want to

state it erroneously.

Anyway, when they pour this "melt," it's blinding blue-white.

And it runs out like water that seems much lighter than any water you have

seen. It just pours out through the channels and you have to wear goggles.

You can't possibly look directly at it. And they'd make these big ingots,

and they go off to the mills. "

|